MODIFICATION MILL

MODIFICATION MILL

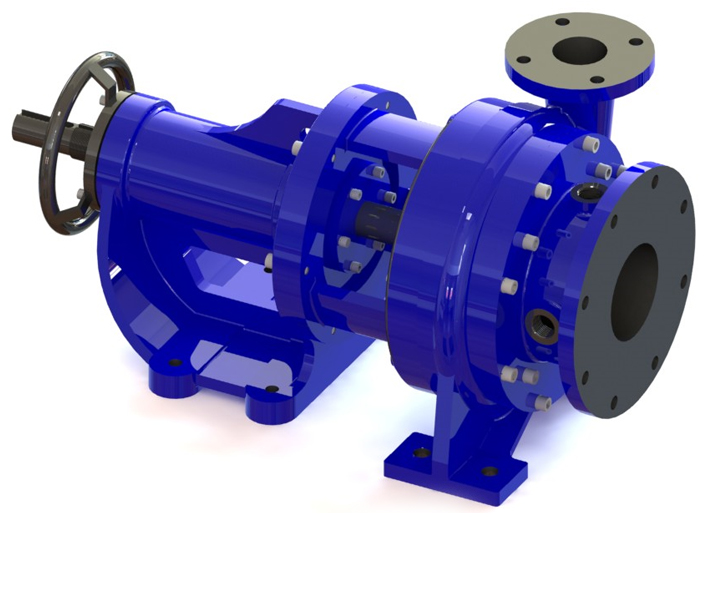

Modification mill is used to disintegrate particles of a liquid having particles inside or both to mix of 2 different liquids with each other and then to disintegrate of their particles.

Inlet of modification mill is Ø 125 mm, outlet is Ø 68 mm. Inlet part of the mill is jacketed. If the liquid passing from inside has freezing property then it is used to warm.

There is 1 rotor and 1 stator inside the body of modification mill which is in snail shape. Rotor can be approached to and receded from stator by moving back and forth by adjustment drum inside bracket of the mill. There are teeth from bigger to smaller from inside to outside on rotor and stator. These teeth mesh mutually each other and ensure mixing and disintegration of liquid passing among them.

Fields of use: Paint, Detergent, Asphalt, Chemistry, Cosmetic etc. industrial fields.

Rotor & Stator material: 8620 – heating process 55- 60 HRC

@2021 Vimpi Viscous Liquid Pumps. All rights reserved.