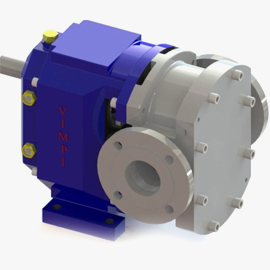

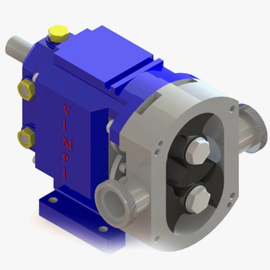

LOBE PUMPS

LOBE PUMPS

Generally, this pump range can be used for the transfer of all kinds of fluids and is particularly suitable for operation in the cellulose, food, chemical, pharmaceutical and beverages (alcoholic and non- alcoholic) industries. The pumps are especially convenient for use where the pump is cleaned is disassembled way and maintenance, safe operation; anti-corrosive properties are of utmost preference.

Lobe pumps have positive displacements and are consisting of two lobes. Lobe which is connected to pump shaft conveys the movement taken from the motor to the other lobe in reverse direction through driving shaft, thereby lobes become distanced from each other and generates vacuum and liquid fills in the pump by the virtue of vacuum generated.

Pump sucks the constant amount of liquid by the virtue of vacuum. The sucked fluid moves from among lobes towards the delivery mouth.

Lobes mesh each other at delivery mouth and create pressure and provide removal of the liquid to the outside. Pump transfers the liquid as much as its volume by every rotation of pump shaft. Henceforth capacity of pump is directly proportional to its size and revolution.

@2021 Vimpi Viscous Liquid Pumps. All rights reserved.