FLAME BURNER

FLAME BURNER

Flame burners are burners that are used in rolling mills, industrial furnaces and equipment, distributor and relay tanks, capable of working with both liquid and gas fuels but provide high temperature.

Designed for burning any kinds of heavy oil, these burners are adjusted for air and fuel separately until they provide maximum fuel saving and they are controlled synchronously by a single level when a good combustion is achieved. The air needed by flame burner is provided by air ventilator or blower.

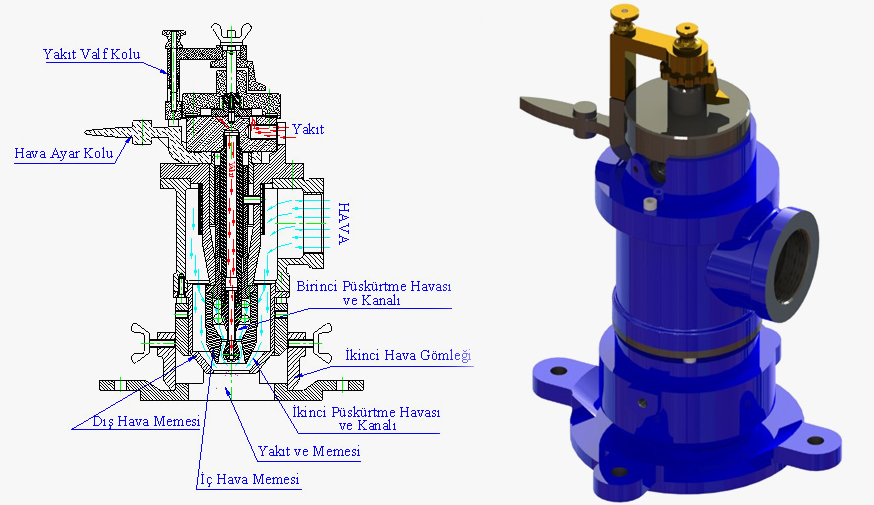

Flame burner mixes fuel and air proportionally and provides occurring of combustion in the high efficiency state. Fuel entering to burner at a definite rate by fuel adjustment mirror is transmitted to nozzle by a fuel pipe. In the meantime whirlpools occur while the air taken into the burner at a certain rate through air adjustment lever passes through the channels inside the burner.

Fuel spraying out pressurized from fuel nozzle and the air coming from air channels begin to mix. Air coming from air channels transforms the fuel exiting from nozzle into dust and combustion is ensured by making ignition. Since air and fuel in the burner is checked at the outlet; negative changes in operation conditions causing to poor combustion become prevented.

@2021 Vimpi Viscous Liquid Pumps. All rights reserved.